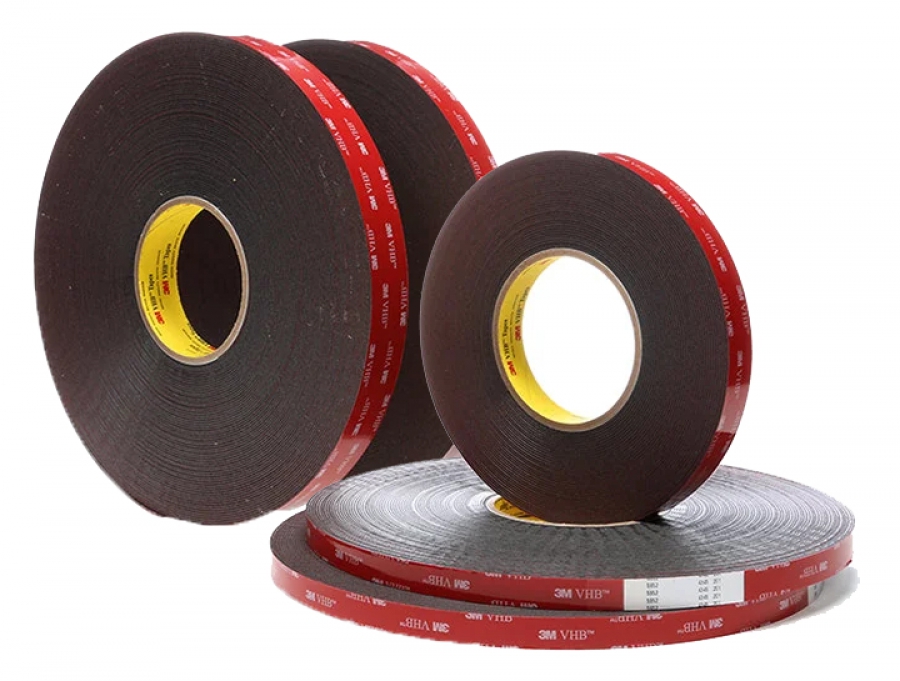

Double-sided tapes 3M

3M Double-sided Tapes: Innovation, Performance and Reliability

3M double-sided tapes are one of the most innovative and advanced products on the adhesive materials market. Thanks to many years of experience and constant pursuit of perfection, 3M has developed technologies that significantly affect the quality and efficiency of applications, regardless of the industry or application. In this article, we will explore the world of 3M double-sided tapes, discussing their features, applications and interesting facts.

Reliability and Performance

One of the key features that distinguishes 3M double-sided tapes is their reliability. The adhesive based on acrylic technologies is characterized by excellent adhesion to various surfaces, both smooth and porous. This means that 3M tapes are able to maintain a stable connection even in difficult environmental conditions, such as variable temperatures or humidity.

Variety of Applications

3M double-sided tapes are used in many industries and fields. They are an indispensable element in industrial production, automotive, electronics, construction, as well as in everyday use. Thanks to their versatility, they are an irreplaceable tool in assembly, fastening, connecting and many other processes.

Resistance to Extreme Conditions

3M brand products are known for their high quality and durability. Double-sided tapes are no exception. They are resistant to UV radiation, chemicals and other aggressive external factors. Thanks to this, they retain their properties even in extreme conditions, which makes them an ideal choice in difficult applications.

Technological Innovation

3M is a brand that constantly invests in research and development. Thanks to this, its double-sided tapes are equipped with the latest technologies. An example of this are VHB (Very High Bond) series tapes, which are characterized by extremely high shear and tensile strength.

Interesting facts about 3M Double-sided Tapes

-

NASA and Apollo 11: In 1969, during the Apollo 11 mission, 3M tapes were used to secure various components inside the spacecraft.

-

Inspiration from Nature: Acrylic adhesives used in the production of 3M tapes were inspired by the structure of amber resin molecules, which are known for their durability.

-

Temperature Resistance: Some 3M tapes can maintain their properties even at extreme temperatures, ranging from -40°C to +230°C.

-

Awards and Distinctions: 3M brand products have repeatedly won prestigious awards for innovation and quality, confirming their excellence.

3M double-sided tapes are symbols of innovation, reliability and versatility. Their impact on various industries and everyday life is invaluable, making them irreplaceable in many applications.