What are LED drivers?

LED drivers are devices that allow you to control and power LEDs. They are essential for the proper operation of LED lighting because they provide stable current and voltage, protect against overheating, and allow you to adjust the brightness and color of the light. In this article, we will present the types of LED drivers, their parameters and applications, and also advise you on how to choose the right driver for your needs.

Types of LED drivers

LED drivers can be divided into two main types: constant current and constant voltage. The difference is that constant current drivers always supply the LEDs with the same current, regardless of the supply voltage, while constant voltage drivers always supply the same voltage, regardless of the current drawn by the diodes. The choice of driver type depends on the type of LEDs you want to power.

Powered element |

Driver type |

|

Constant current drivers

are used to power LEDs in a series circuit, i.e. one in which the diodes are connected one behind the other. In such a circuit, the current flows through all the diodes the same, and the voltage is divided proportionally to the number of diodes. The advantage of this solution is that all the diodes light up equally and there is no risk of one of them burning out. The disadvantage is that the number of diodes in the circuit cannot be freely changed, because this requires changing the supply voltage or the driver. Constant current drivers, often called DRIVERs, are usually used for POWER LED diodes. |

|

Constant voltage driversare used to power LEDs in a parallel circuit, i.e. one in which in which the diodes are connected in parallel to the voltage source. In such a system, the voltage is the same for all diodes, and the current is divided proportionally to the resistance of each of them. The advantage of this solution is that the number of diodes in the system can be freely changed, without having to change the controller or the supply voltage. This type of connection is usually found in LED strips. LED strip controllers regulate the voltage supplied to the LED strip via the so-called PWM (PULSE WIDTH REGULATION) regulations. |

|

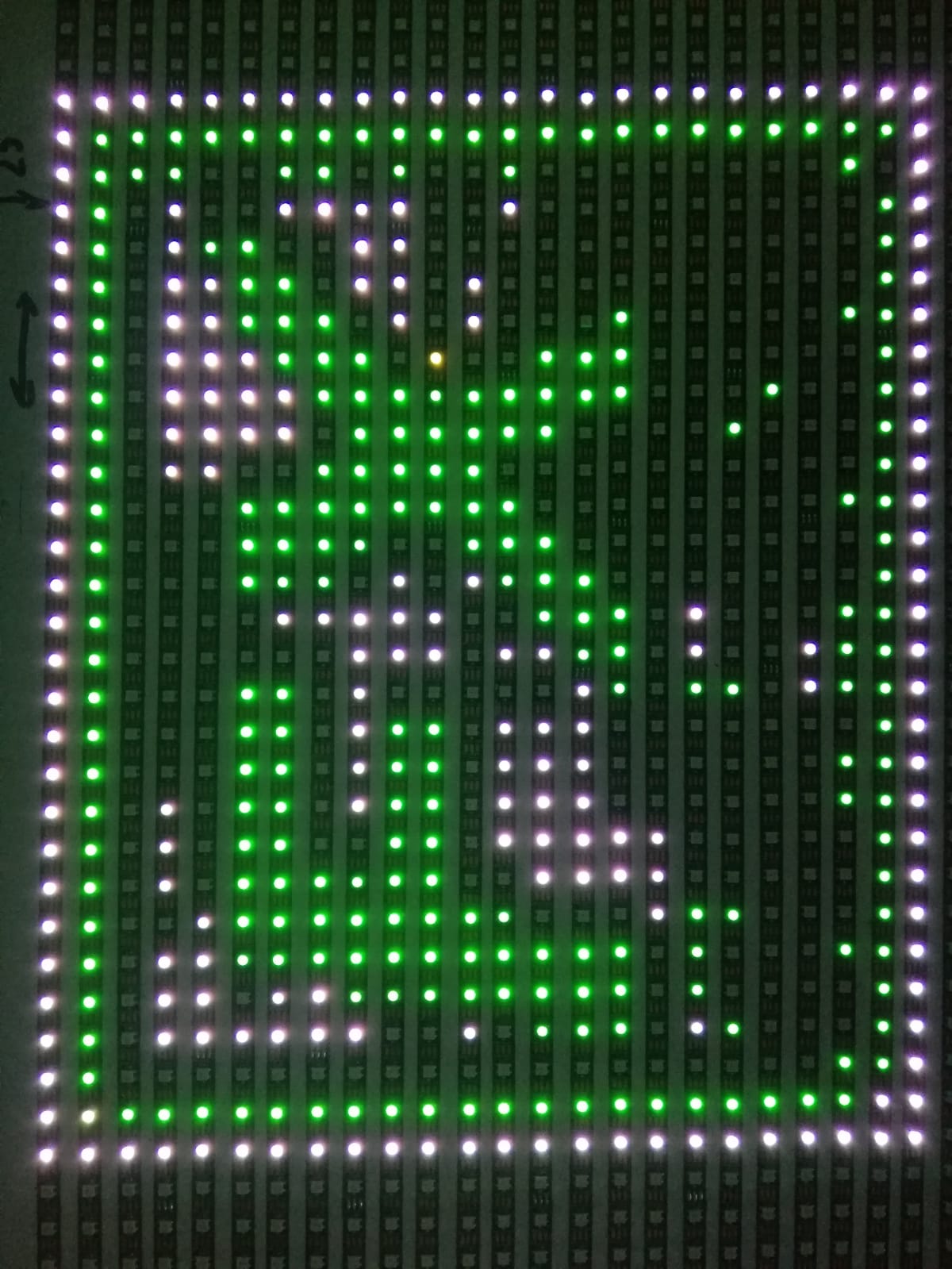

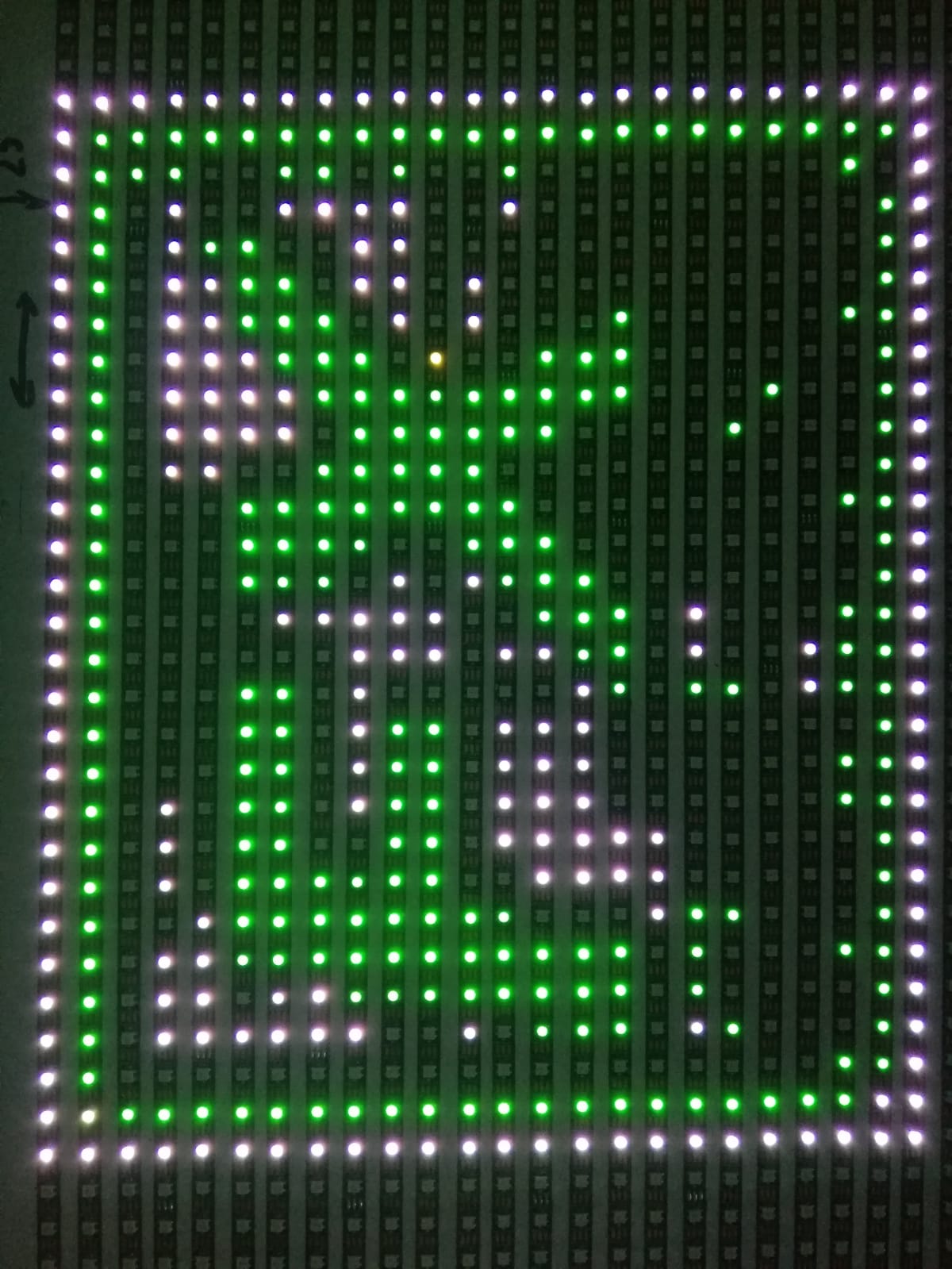

Digital (addressable) drivers- Digital controllers ( RGB Digital ) can also be a very interesting alternative. Here, power control is not carried out using voltage or current, but using a signal informing the diode about its light power using a chain of variables intended for subsequent modules decrypting the signal. Such controllers allow you to control the color and power of any selected diode individually. This gives amazing effects such as imitation of movement or the ability to display animations or even images. |

In the following part, due to the fact that most LED strips and modules are operated by voltage regulation, we will focus on PWM controllers, i.e. known as a mono dimmer, RGB controller or RGBW controller. All these devices belong to the category of voltage regulation controllers. The main difference between MONO RGB or CCT controllers is the number of channels they support. A very interesting

Division of LED controllers by number of channels:

Mono - 1 channel

- used for single-color LED strip that operates in one color. These are all white strips and strips with a uniform, constant color. This controller, although it controls or dims only one color, is usually characterized by high power. There are also small MONO controllers that can even close in an LED profile. Small controllers for LED profiles usually support current up to 6A. Large controllers have a mode of up to 600W and can be synchronized.

CCT - 2 channels

- used for LED strip that changes the temperature of light. CCT or so-called MULTIWHITE strips are all white strips with two shades - cold white and warm white. The light color is adjusted by appropriately selected ratio of power supplying the channel associated with the warm shade and the channel associated with the cold shade. The controller not only sets the balance between light colors. Additionally, the whole thing can evenly dim

RGB - 3 channels

- RGB color strip controller - as the name suggests, the controller manipulates the power of 3 channels, respectively Red Green Blue. The combination of these 3 colors allows you to obtain almost any desired light color.

RGBW - 4 channels

- RGB strip controller extended with a white light channel - because white light obtained using an RGB diode may be too insufficient, RGB control has been additionally extended with white light. The combination of these 3 colors and additional white light allows you to obtain not only any color of light but also naturally added strong white light, the shade of which can also be selected when purchasing the LED strip.

RGB + CCT - 5 channels

- RGB strip controller extended with CCT, i.e. white light temperature regulation - because white light obtained using an RGB diode may be too insufficient, RGB control has been additionally extended with white light. The combination of these 3 colors and additional white light allows you to obtain not only any color of light but also naturally added strong white light, the shade of which can also be selected when purchasing an LED strip.

Addressable strip controllers

Have you ever wondered how those amazing lighting effects you see at concerts, events or exhibitions work? Maybe you would like to create something similar in your home, office or garden? If so, you need to learn about addressable LEDs!

What are addressable LEDs?

Addressable LEDs are a special type of light-emitting diode (LED) that has a built-in integrated circuit (IC) that allows you to control the color and brightness of each diode or group of diodes independently of the others. This allows you to create an infinite number of colors and patterns on a single LED strip that can be cut and combined as desired. These diodes in their initial version are made up of 3 lines:

- - 5V - Power

- - GND - Minus

- - D0 - digital Signal

The signal in digital form is sent as a list of settings for subsequent channels in series. Subsequently placed diodes on the LED tape or matrix receive and delete the first received channel. It can be said that the chain of commands is somehow eaten by subsequent addressable diodes and passed on to the next diode. Such a controller must be compatible with the type of digital diode. First of all, it must be matched to the receiver by the type of diode. So:

The addressable LED driver must be compatible with the diode model by:

- the number and type of channels per diode.

- the total number of channels required by the addressable LED matrix or LED strip

- the supply voltage

The choice of addressable diodes depends on what you want to use them for. Here are some factors to consider:

- Number and arrangement of diodes - the more diodes you want to use, the more current they will draw and the larger the power supply you will need. In addition, if you want to place the diodes in different places, you need to ensure the appropriate length and quality of the signal and power cables to avoid interference and voltage drops.

- Shape and size of the diodes - depending on how you want to place the diodes, you can choose between SMD and THT diodes, as well as between different dimensions and shapes. For example, if you want to create a diode matrix, you can use SMD diode boards or tapes that are easy to connect. If, however, we want to place the diodes at different angles or on uneven surfaces, we can use THT diodes, which are easy to bend and mount.

- Microcontroller type - different types of microcontrollers built into addressable diodes have different properties and requirements. For example, the WS2812B and SK6812 are easy to use because they only require one signal wire, but they have a limited refresh rate and can be susceptible to interference. The APA102, on the other hand, requires two signal wires, but has a higher refresh rate and better stability.

- Supply voltage - digital diodes can be powered by a voltage from 3.3V to 24V. It depends on how the diodes are placed and connected. 3.3V to 5V diodes are strips cut every beak, LED strips addressed 12V have a cutting point every 3 diodes and 24V every 6 diodes.

LED driver parameters

The basic parameters of LED drivers are:

- Input voltage - this is the voltage that must be supplied to the driver from the mains or another power source. It is usually 230 V AC or 12 V DC.

- Output voltage - this is the voltage that is supplied by the driver to the LEDs. It depends on the type of driver and the number and type of LEDs in the system. It can range from a few to several dozen volts.

- Output current - is the current that flows through the LEDs connected to the controller. It depends on the type of controller and the resistance of the LEDs in the system. It can range from a few to several hundred milliamps.

- Output power - is the electrical power that is consumed by the LEDs connected to the controller. It is the product of the voltage and output current. It can range from a few to several hundred watts.

- IP protection class - is a marking that specifies the resistance of the controller to external factors such as dust, moisture, water or mechanical impacts. The higher the protection class, the better the controller is protected. For example, IP20 means that the controller is resistant to finger contact but not to water, while IP67 means that the controller is completely dustproof and waterproof to a depth of 1 meter.

Applications of LED drivers

LED drivers are used in various types of LED lighting, such as:

- LED strips - these are flexible strips with LED diodes that can be glued to various surfaces and shaped as you wish. They are used for decorative illumination of furniture, walls, ceilings, stairs, mirrors or windows. Constant voltage drivers with a voltage of 12 V or 24 V are usually used to power LED strips.

- LED bulbs - these are light sources replacing traditional incandescent or halogen bulbs. They are characterized by high durability, low energy consumption and the ability to adjust the brightness and color of the light. LED bulbs are usually powered by 230 V or 12 V constant current drivers.

- LED panels - these are flat plates with LED diodes that are used to illuminate the interiors of homes, offices, shops or warehouses. They provide even and bright light that does not strain the eyes and does not generate heat. LED panels are usually powered by 230 V or 12 V constant current drivers.

- LED spotlights - these are powerful light sources used to illuminate large outdoor or indoor areas, such as playing fields, parking lots, halls or stages. They have high resistance to weather and mechanical conditions and the ability to adjust the angle of light. LED spotlights are usually powered by 230 V or 12 V constant current drivers.

How to choose the right LED driver?

To choose the right LED driver, check the following parameters:

- LED type - are they constant current or constant voltage diodes. This can be checked on the packaging or in the technical specifications of the diodes.

- Number of LEDs - how many diodes do you want to connect to one controller. This can be checked on the packaging or in the technical specifications of the diodes.

- LED operating voltage and current - what voltage and current are needed for the diodes to light up properly. This can be checked on the packaging or in the technical specifications of the diodes.

- Power consumed by LEDs - what is the sum of the power of all diodes connected to one controller. This can be calculated by multiplying the voltage and operating current of each diode and adding the results.

- Controller input voltage - what voltage must be supplied to the controller from the mains or other power source. It is usually 230 V AC or 12 V DC.

- Controller output voltage - what voltage must be supplied by the controller to the LEDs. It must be equal to or greater than